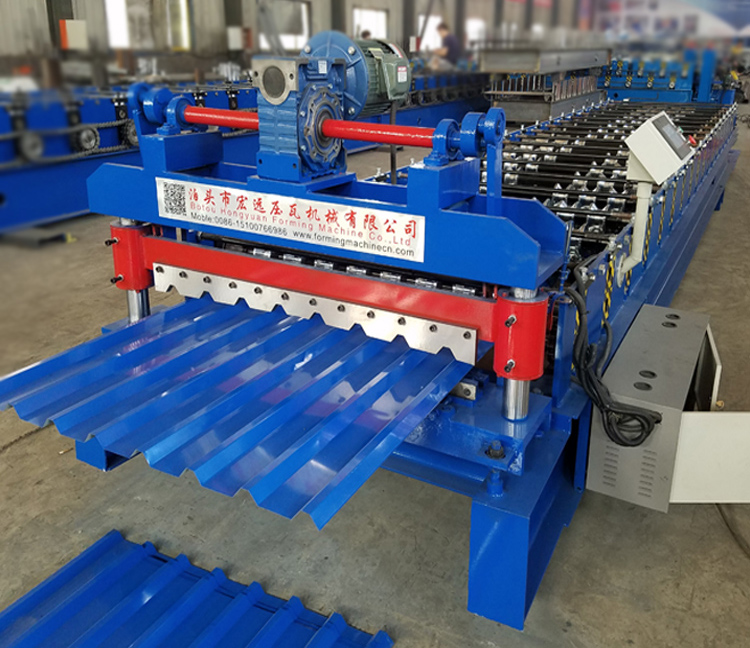

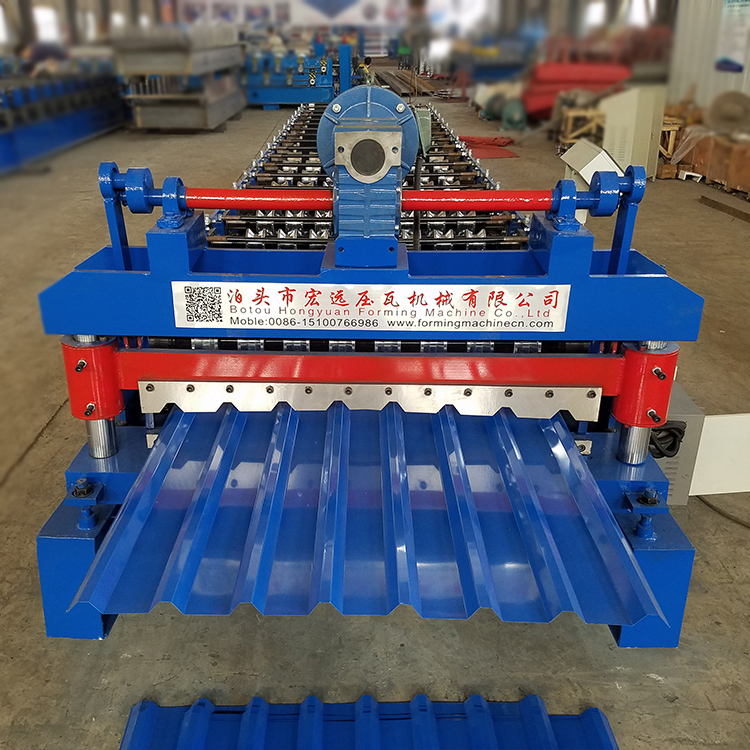

IBR Roofing Sheet Cold Roll Forming Machine

- Packaging:

- one 20ft container for loading one set machine with manual decoiler

- Productivity:

- 30 Sets/Month

- Brand:

- Hongyuan

- Transportation:

- Ocean

- Place of Origin:

- Hebei,China

- Supply Ability:

- 30 Sets/Month

- Certificate:

- ISO

- Port:

- Tianjin Sea Port

Basic Info

Model No.: IBR-8

Product Description

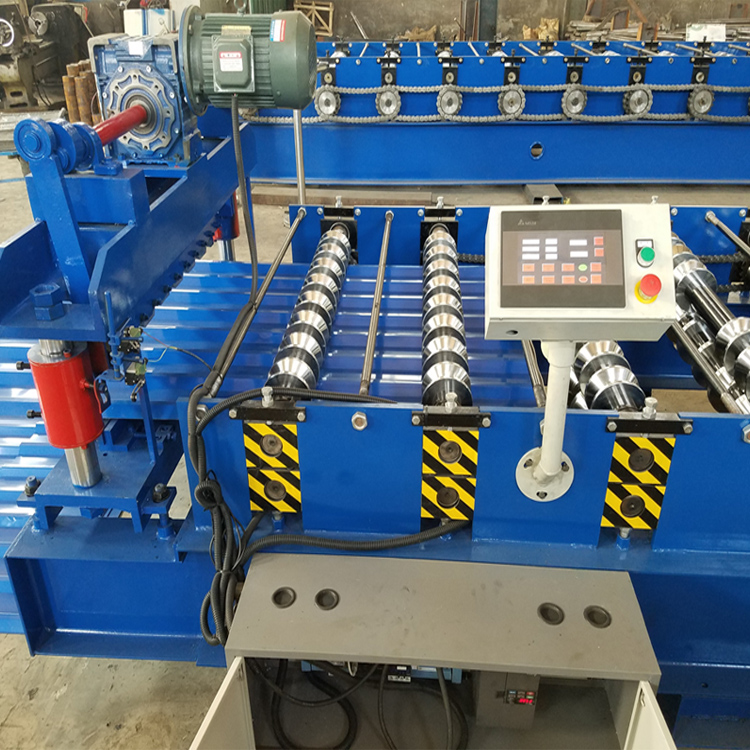

IBR Roofing Sheet Cold Roll Forming Machine

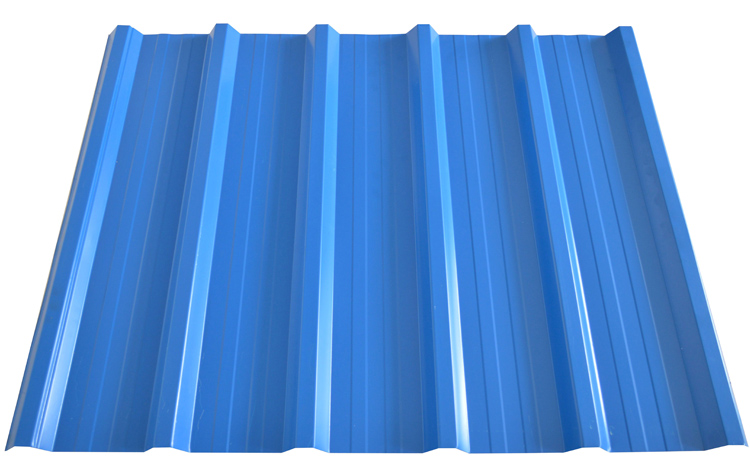

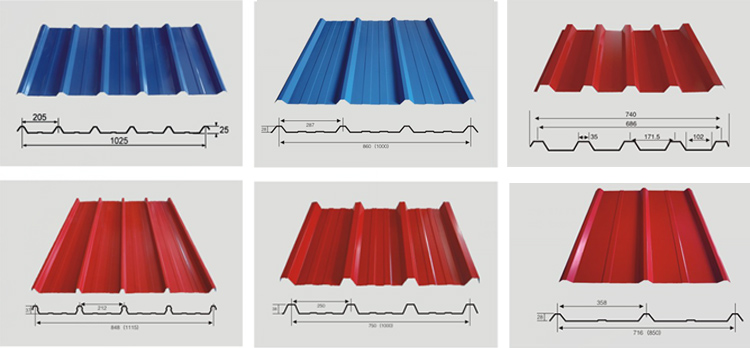

The High Speed Sheet trapezoidal Roll Forming Machine produced by this Colored Steel Roofing Sheet ,Trapezoidal Roll Forming Machine are widely used in all kinds of factories, houses, warehouses and simple steel shed, and with beautiful appearance, high efficiency .

IBR Sheet Roll Forming Machine Parameters :

| IBR Roofing Sheet Cold Roll Forming Machine | |

| Suitable to Process | Color steel sheet/Galvanized sheet/Iron sheet/Aluminum sheet/Stainless steel sheet |

| Width of raw material | 1000 mm/1200 mm/1250 mm (according to customer requirements,please provide profile drawing) |

| Rollers | customized |

| Dimensions | 7000*1550*1300 mm |

| Power | 5.5+4kw |

| Thickness of sheet | 0.3-0.8 mm |

| Material of cutting blade | Cr 12 |

| Diameter of the roller | customized |

| Voltage | 380 V |

| weight | about 3 T-5 T |

| Productivity | 10-18 m/min |

| Control system | PLC control |

2. Blade and mold material : GCR 12 steel with quenched treated 60-62℃

It can decide cut panel dimension according to the hydraulic drive and PLC computer control system

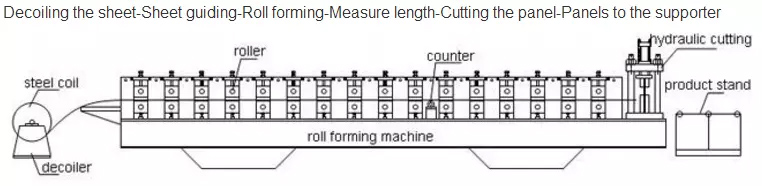

feeding table

It is used to control the width and position of the steel sheet.

The sheet is guided into the machine with correct position, to make sure the panel is neat and parallel.

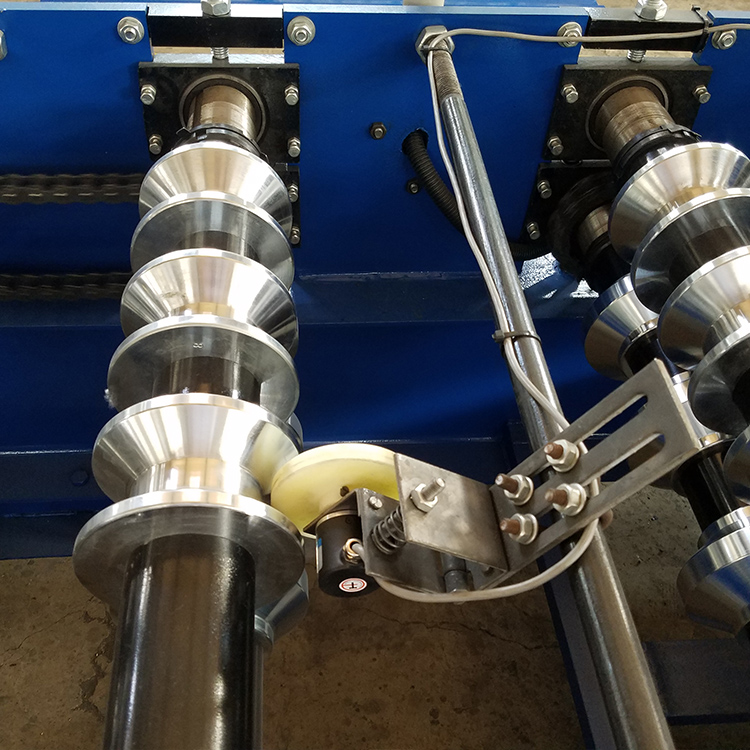

Roller System

1. Material: high grade NO.45 forged steel.

2. Roller station: 11-16(depends on final design)

3. Thickness of feeding material:0.3-0.8 mm

Automatic Control System

1. Screen: touch screen or text screen

2. Automatic length measurement

3. Automatic quantity measurement

4. Computer is used to control length and quantity. Machine will automatically cut to length and stop when required quantity is achieved.

5. Length inaccuracy can be amended easily.

We also can custom the roof sheet roll forming machine that you want

Company Profile

Botou Hongyuan Forming Machine Co.,Ltd has been established in 2005 as a professional manufacturers of roof tile roll forming . We use AUTO CAD design software. With more then 10 years of experiences and strict quality control, our roof sheet roll forming machines meet International Standard. We are the leading manufacturer and reported of roll forming machine in China. We manufacture various kinds of roll forming machine for producing the following products. Our Roll Forming Machine contain Glazed Roof Tile Roll Forming Machine,Trapezoidal Roll Forming Machine ,Corrugated Roll Forming Machine , Double Layers Roll Forming Machine ,C Z Purlin Roll Forming Machine , Steel Structure Floor Deck Forming Machine etc.

Packaging Details:

1. one 40ft container for loading one set machine with manual decoiler;

2. the whole Wiped Anti Rust Oil, PLC controller covered by foam film;

3. Spare parts and some small parts packed in plastic tooling box;

4. All Components Fixed by steel wire with Container.

Contact us if you need more details on Roll Forming Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about IBR Sheet Roll Forming Machine、Cold Roll Forming Machine. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Roof Tile Roll Forming Machine > Trapezoidal Roll Forming Machine